Industrial distribution refers to the complex ecosystem that integrates suppliers, warehouses, transportation networks, and technology to maintain the momentum of industrial operations. It facilitates the movement of products from manufacturers to end-users. Without it, factories stop, stores empty, and construction halts. It is the critical link ensuring the seamless flow of materials and products between nations and companies.

Right now, the industry is in flux. Fundamental shifts, such as rapid technological changes, shifting global markets, and evolving customer expectations, are reshaping the industrial distribution landscape. Thus, the future of industrial distribution is one of change, and adapting to these changes is crucial for business success in this sector.

Here are the emerging trends that are set to shape the next few years in industrial distribution:

- The growth of ecommerce

- Using data and analytics to drive distribution success

- Optimizing distribution networks for the future

- Preparing the workforce for future distribution demands

The Growth Of eCommerce In Industrial Distribution

More and more businesses are turning to online platforms to purchase industrial goods, and this trend is only set to grow.

This shift is changing traditional distribution methods. Instead of relying solely on sales reps and catalogs, you now need to think about things like:

- User-friendly online platforms

- Digital product catalogs

- Online ordering and tracking systems

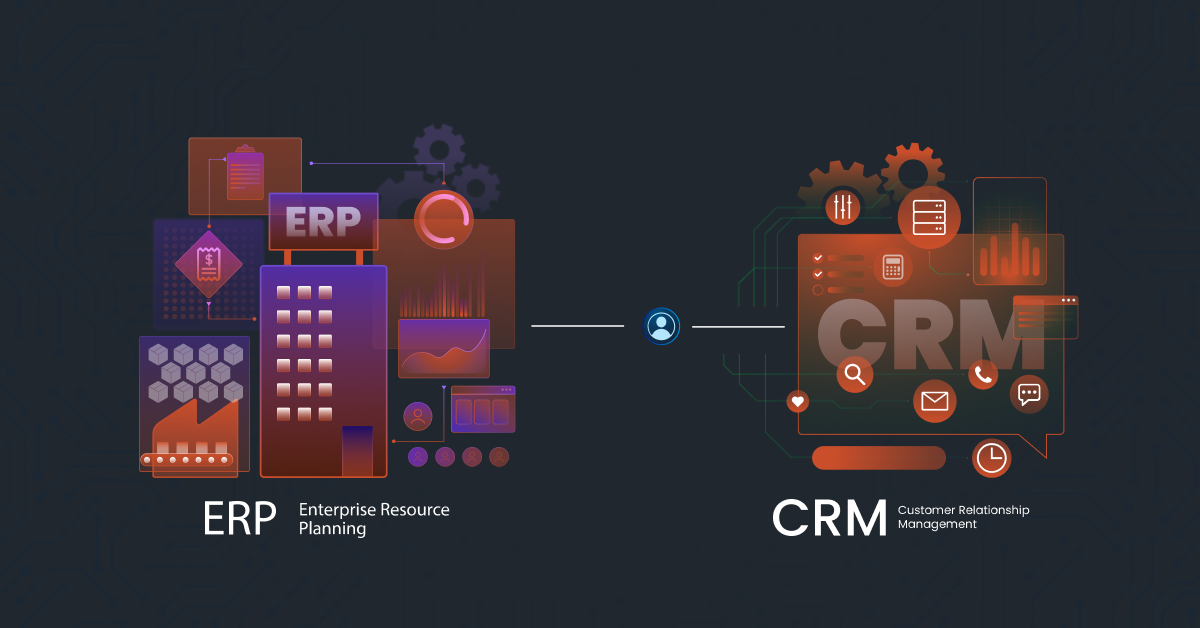

- Integration with customer procurement systems

There’s also a growing trend towards direct-to-consumer models, even in the industrial space. This means you might find yourself competing with manufacturers who are selling directly to end-users.

To succeed in an ecommerce-driven market, you’ll need to focus on:

- Creating a seamless online experience

- Providing detailed product information and support

- Offering flexible delivery options

- Using data analytics to personalize the customer experience

Using Data and Analytics to Drive Distribution Success

The ability to collect, analyze, and act on data gives you a significant competitive edge in industrial distribution.

Real-time data is particularly crucial for effective supply chain management. It allows you to:

- Forecast demand more accurately

- Optimize inventory levels

- Identify and resolve issues quickly

- Make informed decisions about pricing and product mix

Companies that have successfully leveraged data-driven strategies have seen impressive results. For example, some distributors have used predictive analytics to enhance operational efficiency by up to 30%. Businesses that have critical information stashed away in different systems can access real-time data through integrating these systems.

Also see: Understanding The Data Integration Process

Optimizing Distribution Networks for the Future

The structure of distribution networks is evolving. There’s a growing trend towards more regional and local distribution centers instead of large centralized warehouses.

This stems from the desire to get manufacture/production closer to the customer, which enables:

- Reduce delivery times

- Lower transportation costs

- Improve flexibility in meeting local demand

Based on your specific business needs and customer expectations, you’ll need to carefully weigh the pros and cons of global versus localized distribution approaches.

Preparing the Workforce for Future Distribution Demands

The industrial distribution sector demands a workforce equipped with technical knowledge and business acumen. To meet this need, many universities now offer specialized industrial distribution programs, culminating in a Bachelor of Science degree. These programs provide a comprehensive education in distribution management, operations management, and industrial technology, preparing graduates for careers ranging from sales manager to entrepreneurship in the field.

As the industry evolves, future-facing companies must look to hire new talent with the skill set that an industrial distribution degree might provide. Furthermore, automation is changing the nature of many distribution jobs and creating new opportunities.

There’s a growing need for specialized skills in areas like:

- Data analysis

- Supply chain management

- eCommerce operations

- Robotics and automation maintenance

Many companies are investing heavily in training and development programs to meet these demands. The education sector is also pushing to create programs that prepare future professionals for careers in modern industrial distribution.

Key Challenges Facing Industrial Distribution

1. Tackling Supply Chain Disruptions

Supply chain disruptions pose significant challenges to industrial distributors. Global pandemics, natural disasters, and geopolitical tensions can severely impact carefully orchestrated operations.

The consequences of these disruptions extend beyond operational inconveniences, potentially causing substantial financial repercussions. Late deliveries, stockouts, and customer dissatisfaction are merely surface-level issues. The core challenge lies in maintaining operational continuity in unforeseen circumstances.

Distributors are responding by constructing more resilient supply chains. Strategies include supplier diversification, increased safety stock, and investment in advanced forecasting tools.

Moreover, inventory management assumes critical importance in this context. Striking the optimal balance between maintaining sufficient stock to meet demand and avoiding excessive capital tie-up in inventory is crucial. This delicate equilibrium is fundamental to successfully navigating supply chain disruptions.

2. Adapting to New Technologies in Distribution

Technology is rapidly transforming industrial distribution. Warehouse automation and predictive analytics are among the tools revolutionizing business operations.

Key technological trends include:

- Artificial Intelligence (AI) for demand forecasting

- Internet of Things (IoT) for real-time tracking

- Blockchain for supply chain transparency

- Robotic Process Automation (RPA) for warehouse efficiency

These technologies offer powerful capabilities to enhance operational speed, intelligence, and efficiency. The challenge here lies in NOT adopting them – if companies fail to implement these technologies successfully, they will inevitably be left behind those that do.

And technology implementation presents its own set of challenges:

- Substantial initial investment

- Requirement for specialized skills

- Potential employee resistance to change

- Integration complexities with existing systems

A strategic approach to technology adoption is crucial. Begin with small-scale implementations, validate concepts, and then expand. It is imperative to ensure that technology serves business objectives, rather than dictating them.

Also see: AI in Supply Chain Management for Distributors

3. Cybersecurity Requirements in a Technology-Based Ecosystem

Cybersecurity investment is now fundamental to maintaining trust, ensuring operational resilience, and preserving supply chain integrity.

Paramount among these is the implementation of technology, such as ransomware attack protection solutions, to safeguard sensitive customer and business data and intellectual property, all of which are critical concerns in an industry where proprietary information can be a significant competitive advantage.

Equally important is maintaining supply chain integrity, ensuring the authenticity of transactions, and preventing unauthorized alterations that could disrupt operations or lead to financial losses. Operational continuity is another key concern, as cyber-attacks that risk everything from customer identity theft to business resource theft have the potential to paralyze distribution networks.

4. Global Economic Shifts and Their Impact on Distribution

International events significantly influence business operations. Trade conflicts, regulatory changes, and economic uncertainties are pivotal in shaping the distribution landscape.

For instance, tariffs and trade policies impact product costs and availability, subsequently affecting sourcing strategies and pricing models.

Thus, it is essential to build a resilient and flexible distribution network, which involves:

- Diversifying the supplier base

- Exploring new market opportunities

- Strengthening key partner relationships

- Developing comprehensive contingency plans

The objective is to create a distribution network capable of withstanding global economic fluctuations without compromising operational integrity.

5. Moving Toward Sustainability in Distribution

Customer demand for environmentally responsible options and increasing regulatory pressures are driving the industry towards greener practices.

However, the importance of sustainability extends beyond environmental conservation. Sustainable practices can yield cost savings, enhance operational efficiency, and improve brand reputation.

Distributors are implementing various measures to reduce their environmental impact:

- Optimizing transportation routes to minimize emissions

- Adopting eco-friendly packaging materials

- Implementing energy-efficient warehouse technologies

- Collaborating with environmentally conscious suppliers

The challenge lies in balancing sustainable practices with cost efficiency. While achieving this balance can be complex, thoughtful planning and innovative approaches can yield solutions beneficial to both environmental and financial objectives.

Related read: Technology For Sustainability: Insights From Luis Ruesga

Strategies for Maintaining Competitiveness in Industrial Distribution

So, given the direction the industry is moving, and the trends we can expect to see in the future, how can businesses adapt and even preempt these trend shifts? Not surprisingly, using data to focus on customer experience is the most fundamental way to future-proof your business.

Leveraging Digital Tools for Competitive Advantage

Digital transformation is imperative for maintaining competitiveness in the contemporary industrial distribution landscape. The strategic implementation of digital tools enhances operational efficiency, decision-making processes, and customer service quality.

Successful digital strategies encompass:

- Deployment of AI-powered chatbots for customer support

- Implementation of IoT sensors for real-time inventory tracking

- Utilization of cloud-based platforms for seamless collaboration

It is crucial to recognize that digital transformation extends beyond mere technological adoption. It necessitates a fundamental shift in organizational mindset and culture, permeating all aspects of operations.

Enhancing Customer Experience in Distribution

In an era characterized by Amazon-like experiences, customer expectations have risen dramatically, even in B2B contexts. Prioritizing customer experience serves as a key differentiator in industrial distribution.

Technology can be leveraged to enhance service and satisfaction through:

- Self-service portals facilitating easy ordering and tracking

- Personalized recommendations based on purchase history analysis

- AR/VR applications for product demonstrations and training

However, technology alone is insufficient. Strengthening relationships with retailers and partners is essential. This involves regular engagement, collaborative problem-solving, and exceeding expectations in meeting their needs.

Next-Gen Sales Strategies for Contemporary Distribution

The role of sales in industrial distribution is undergoing a significant transformation. As transactions increasingly migrate online, sales teams must evolve from order-takers to trusted advisors.

This evolution demands a combination of technical expertise and traditional sales acumen. Sales professionals must:

- Possess in-depth understanding of complex products and systems

- Provide valuable insights and solution-oriented approaches

- Cultivate and maintain long-term customer relationships

Professional development is crucial in this context. It is highly recommended that you invest in comprehensive training programs that address both technical skills and soft skills, such as communication and problem-solving.

Looking Ahead to the Future of Distribution

The industrial distribution sector faces a landscape characterized by both significant challenges and substantial opportunities. Supply chain vulnerabilities, technological advancements, sustainability imperatives, and evolving customer expectations collectively shape the industry’s trajectory.

Proactive engagement with these challenges presents opportunities for growth and innovation. Success in this dynamic environment hinges on adaptability, embracing change, and maintaining a forward-looking perspective.

Key attributes of successful future distributors include:

- Agility in responding to market fluctuations

- Strategic leveraging of technology to enhance efficiency and customer experience

- Development of resilient and sustainable supply chains

- Investment in workforce development and fostering a culture of innovation

- Protecting business and customer data from increased cyber risks

Integrating these trends and challenges into strategic planning and decision-making processes is imperative. Embracing innovation and exploring novel approaches is crucial for maintaining competitiveness.

The future of industrial distribution offers significant potential for those prepared to navigate its complexities. Industry leaders and participants must shape this future through strategic foresight and decisive action.

Contents