Supply chain management must address common problems of PL integration as businesses grow. Smooth operations require efficient communication and data exchange with third-party logistics providers (3PL). Electronic Data Interchange (EDI) helps here. It streamlines regular business transactions and messages between business partners.

3PL EDI integration links your business systems to 3PL suppliers using EDI standards and technology platforms. Automating the logistics flow of data and eliminating human intervention improves business operations, such as order processing, inventory management, shipment, and business performance.

Third-party logistics providers play a crucial role in helping eCommerce businesses meet customer needs. DCKAP Integrator streamline and scale this procedure. Integrating is simple with their central platform.

Key Components of 3PL EDI Integration

EDI system integration in 3PL providers involves various components. They work together to enable seamless communication between businesses and their logistics providers.

They guarantee the accurate and efficient exchange of data by enhancing operational efficiency. This enables smoother supply chain operations.

1. EDI Standards

EDI standards are formats that define how to organize and send data between different systems.

Common Standards:

- ANSI X12: Widely used in North America.

- EDIFACT: Common in Europe and international markets.

- TRADACOMS: Used in the UK retail industry.

Role in 3PL Integration:

These standards ensure your system works with the 3PL providers, no matter the software used.

2. EDI Document Types

EDI uses specific transaction sets to facilitate communication. Each set represents a particular business document. EDI orders include:

Common 3PL EDI Documents:

- Document 850 (purchase order) notifies the 3PL about new orders.

- Document 940 (warehouse shipping order) provides shipping instructions.

- Document 856 (Advance Shipping Notice) provides details about the shipping process.

- Document 945 (Warehouse shipping advice) confirms shipment details.

- Document 997 (functional acknowledgment) confirms receipt of EDI transactions.

- Advance Ship Notice (ASN) for detailed shipping updates.

- Document 943 (Warehouse Stock Transfer Shipment Advice and Warehouse Inventory Adjustment Advice) for Stock Changes.

Role in 3PL Integration:

Each document type automates specific tasks. It reduces manual work and ensures accurate communication. These enable seamless data sharing with PL warehouses and brand manufacturers.

3. Communication Protocols

Communication protocols determine how EDI documents are transmitted between systems.

Common Protocols:

- AS2 (Applicability Statement 2): EDI over the internet is safe and widely used.

- FTP/SFTP: File sharing protocols that can be used to send and receive EDI files.

- API-based EDI: Modern method for real-time data exchange.

Role in 3PL Integration:

Protocols ensure secure and reliable data transfer between your business and 3PL providers.

4. Data Mapping and Translation

Data mapping translates EDI data into a format your systems can understand, and vice versa. It synchronized across back-office systems to reduce extra work.

Role in 3PL Integration:

- This ensures that EDI data, like inventory levels and orders, is added to your ERP (Enterprise Resource Planning) or warehouse system.

- Tools like the DCKAP Integrator automate this, reducing errors and setup time.

5. Middleware or Integration Platform

Middleware is a bridge between your system and your 3PL provider. It handles data translation, mapping, and transmission.

Role in 3PL Integration:

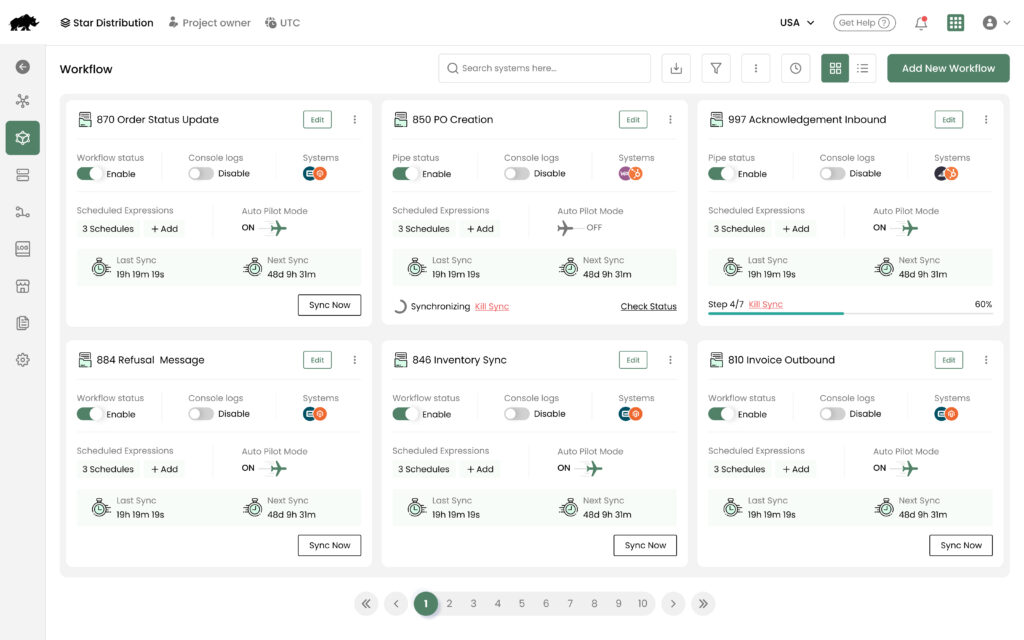

Middleware platforms, such as the DCKAP Integrator, simplify integration by:

- Managing multiple EDI connections.

- Translating data formats for system compatibility.

- Providing real-time visibility into data flows.

- Automates business processes for improved business performance.

6. Error Handling and Monitoring

Processes and tools to detect, report, and resolve errors in EDI transactions.

Role in 3PL Integration:

- It ensures smooth operations by fixing issues. These include missing data or mismatched formats.

- Tools like the DCKAP Integrator send real-time error alerts. They prevent supply chain disruptions.

Related read: Top 18 ERP Integration Tools & Platforms

7. Scalability and Cloud-Based Solutions

Modern EDI solutions use the cloud to handle more transactions. They also add new 3PL partners easily.

Role in 3PL Integration:

Cloud-based platforms like the DCKAP Integrator ensure flexibility and scalability. They let businesses grow without overhauling their systems.

8. Compliance and Security

EDI systems must comply with industry regulations and ensure secure data transmission.

Role in 3PL Integration:

- Protocols like AS2 offer encryption and digital signatures for secure communication.

- Compliance with industry standards prevents legal and operational issues.

9. Reporting and Analytics

Reporting tools provide insights into the performance and efficiency of EDI transactions.

Role in 3PL Integration:

- It enables monitoring of key metrics. These include order accuracy, fulfillment speed, and error rates.

- Tools like the DCKAP Integrator offer dashboards and analytics for better decision-making.

Also see: Understanding EDI Shipping Integration [Methods + Process]

Benefits of 3PL EDI Integration

Increased Efficiency and Automation

3PL EDI simplifies tasks like placing orders and keeping track of shipments. It cuts down on physical work. Routine jobs are sped up, like entering data and checking for mistakes. This gives employees more time to work on more important tasks.

Enhanced Accuracy and Reduced Errors

Manual data entry is prone to human errors. This can cause incorrect inventory counts, delayed shipments, or mismatched orders. EDI ensures accuracy by transmitting data directly between systems, reducing costly mistakes.

Real-Time Visibility and Tracking

EDI enables real-time updates on inventory, orders, and shipments. This openness helps companies gain insight into shipments and warehouse space, make choices based on data, and give better customer service.

Cost Savings and Scalability

EDI lowers management costs. It does this by reducing manual work and delays. EDI is simple to expand as a business grows. It can handle more activities without costing too much more.

Improved Customer Satisfaction

Customers are happier and more loyal when orders are quick, accurate delivery date, correct, and updated in real-time.

Common Challenges and Best Practices

3PL EDI integration has many benefits. But it has challenges, too. Companies need to solve these for a smooth implementation. This is a detailed look at the most common challenges and strategies to overcome them.

1. Complexity of Data Mapping and Standardization

EDI relies on strict standards. Businesses must map their data to them. This process is complex. Different 3PL providers use varying EDI formats. This requires customized mappings for each provider.

Impact:

Errors in data mapping can cause incorrect orders, inventory mismatches, or failed transactions.

Solution:

- Use tools like the DCKAP Integrator. It automates data mapping and provides templates for common EDI documents.

- Collaborate with your 3PL provider to define clear data mapping requirements upfront.

2. System Incompatibility

Many businesses use legacy systems. They may not support modern EDI standards or protocols. Similarly, 3PL providers may have different levels of technological sophistication.

Impact:

Incompatibility can lead to communication failures, delays, or incomplete data exchange.

Solution:

- Use middleware or integration platforms like the DCKAP Integrator. They can bridge gaps between incompatible systems.

- Consider migrating to cloud-based or API-driven EDI solutions for greater flexibility and scalability.

3. High Implementation Costs

EDI integration often needs a big upfront investment in software, hardware, and development. Customizations for multiple 3PL providers further increase costs.

Impact:

Small to mid-sized businesses may find it difficult to allocate the necessary resources.

Solution:

- Use cost-effective, subscription-based EDI solutions like the DCKAP Integrator. They reduce upfront costs and are scalable.

- Start with critical EDI transactions and expand as needed to manage costs effectively.

4. Lack of Standardization Across 3PL Providers

Every 3PL company has its own set of EDI rules, procedures, and transaction sets that they use. This lack of consistency makes integration harder. It’s especially true when using multiple 3PL providers.

Impact:

Businesses must manage multiple EDI implementations, increasing complexity and potential for errors.

Solution:

- Use an integration platform like DCKAP Integrator that supports multiple standards and protocols.

- Centralize the management of EDI connections to ensure consistency across providers.

5. Managing Real-Time Data and Updates

Inventory, orders, and shipping details are often updated in real-time during EDI transactions. It can be challenging to keep all systems in line, especially when there are a lot of transactions going on.

Impact:

Delays or inaccuracies in real-time updates can harm customers and operations.

Solution:

- Use real-time monitoring tools, like DCKAP Integrator’s, to track data flows. They ensure timely updates.

- Prioritize robust testing during implementation to identify and resolve synchronization issues early.

6. Error Handling and Resolution

In EDI transactions, mistakes often occur. These include missing fields, wrong data formats, carrier information, and failed transfers. Finding and fixing these mistakes can take a lot of time and technical expertise.

Impact:

Unresolved errors disrupt supply chain operations and impact customer satisfaction.

Solution:

- Use automated error detection and notification systems to identify issues promptly.

- Use the DCKAP Integrator. It has detailed logs and error-fix workflows to help troubleshoot.

7. Scalability Issues

As businesses grow, the volume of EDI transactions and 3PL partners rise. Legacy systems or manual processes may struggle to handle this growth.

Impact:

Operational inefficiencies arise, leading to delayed order processing and reduced customer satisfaction.

Solution:

- Adopt scalable, cloud-based EDI solutions like the DCKAP Integrator. They can handle more transactions and easily onboard new partners to meet future needs.

- Plan for scalability during the initial implementation phase to avoid future bottlenecks.

8. Change Management and Staff Training

To switch to EDI, we need to change existing processes. Staff who aren’t familiar with the tech need a lot of training.

Impact:

Change resistance or poor training can disrupt processes and reduce productivity.

Solution:

- Provide comprehensive training programs for employees on EDI processes and tools.

- Choose easy-to-use platforms like the DCKAP Integrator. They have a low learning curve and help teams adapt.

9. Security and Compliance Concerns

EDI transactions contain private company data. So, safety and rules are vital. But it can be challenging to make sure that contact is safe and legal.

Impact:

Data breaches or non-compliance can result in financial penalties and reputational damage.

Solution:

- Use secure communication protocols like AS2 or SFTP to encrypt data during transmission.

- Partner with providers like DCKAP Integrator. They must meet industry standards and have built-in compliance features.

10. Integration with Internal Systems

It takes a lot of work to keep data consistent and in sync when EDI is connected to internal systems like ERP, WMS, or TMS.

Impact:

Poor integration can result in fragmented data, duplicate records, or process inefficiencies.

Solution:

- Use an integration platform like DCKAP Integrator. It has pre-built connectors for popular ERP, WMS, and TMS systems.

- Conduct thorough testing to validate that data flows correctly across all systems.

Also see: EDI Integration with ERP Explained [+ Types, Benefits & Challenges]

How DCKAP Integrator Addresses These Challenges

The DCKAP Integrator is a powerful ERP integration tool. It streamlines and improves 3PL EDI integration processes. Here’s how it addresses the evolving trends in this domain:

1. Customized Integration

The DCKAP Integrator becomes a great choice for businesses seeking to customize the integration to fit more seamlessly into their business processes. The tool:

- Can be customized in-house by a team of integration experts

- Allows beyond EDI Integrations: it can built seamless flow of data to other tools including ERP, CRM, ecommerce, PIM etc.

2. API and EDI Synergy

DCKAP Integrator combines traditional EDI with modern APIs. It enables real-time data exchange and flexible communication between systems.

3. Cloud-Based Scalability

It is a cloud-based solution. It offers scalability, lower operational costs, and simple integration with partners. It adapts to changing business needs.

4. Enhanced Security and Compliance

The platform uses strong encryption and industry standards to secure data. This maintains integrity and trust among trading partners.

5. Improved Collaboration

DCKAP Integrator connects businesses and PL providers. It boosts coordination and supply chain efficiency.

6. Support for Sustainable Practices

The platform helps eco-friendly supply chains. It does this by optimizing routes and improving inventory management.

In summary, DCKAP Integrator meets key trends in 3PL EDI integration. It offers advanced tech integration, API (application programming interface), EDI synergy, and cloud scalability. It has better security, improved collaboration, and support for green practices.

Conclusion

Efficient 3PL EDI integration is now essential for businesses. They must meet customer expectations and speed up operations in a dynamic supply chain. Tools like DCKAP Integrator and other EDI platforms bridge the gap between businesses and their 3PL providers.

They ensure efficiency, data accuracy, and seamless communication and address common problems such as EDI connection errors, enabling real-time communications with third-party logistics providers.

DCKAP Integrator combines modern integration with strong EDI. It solves the complexities of 3PL EDI integration. It is scalable and has real-time monitoring, pre-built templates, and central management. By using these tools, businesses can improve their supply chains. They can also save money and boost customer satisfaction in the long run. Reach out to our integration experts to see how to optimize EDI in your business processes.

FAQs

What is 3PL?

3PL stands for Third-party logistics. These allow businesses to outsource their logistics and fulfillment, allowing them to focus on more critical business processes.

What is EDI in 3PL?

Electronic Data Interchange, or EDI, is the main way that different companies talk to each other digitally. It lets you automatically share business documents with a third-party logistics company in a PL warehouse facility setting. This eliminates paper documents and extra work caused by human intervention.

This integration process ensures that many tasks, such as warehouse inventory adjustment advice and 943 – warehouse stock transfer shipment advice, can be done without problems. These tasks include tracking inventory, processing orders, organizing shipments, and creating invoices. Standardized standards, like X12 or EDIFACT, make sure that all systems can work with each other.

EDI experts help your business and 3PL service work together. It lets you see what’s going on in the supply chain and get information in real-time. Businesses can make things easier with tools like DCKAP Integrator. They can handle multiple EDI links and make sure that all of them work well with each other.

How can ERP, WMS or TMS integration play a role in 3PL Integration?

To share data, we must connect with ERP, WMS, and TMS:

- Makes sure that info on orders, inventory, and shipments is always up to date.

- It helps automate the whole process, from taking orders to delivering them. It ensures all PL operations are accurate and aligned.

What are the main types of EDI?

Here are some types of EDI:

- Direct or Point-point EDI

- EDI via AS2

- EDI via VPN or FTP/STP

- Mobile EDI

- Web EDI

Contents