Businesses in various industries use both electronic data interchange (EDI) and application programming interfaces (APIs) to automate business processes. But, each technology serves a different purpose. While EDI works well for sending electronic documents, APIs automate the parts you choose in software systems.

This blog post will explain the logistical and technical differences between each technology in businesses involved in the supply chain. Here, you’ll also discover a way to integrate both technologies into your business seamlessly.

EDI vs. API: Key Differences

| Factor | EDI | APIs |

| Purpose | Sending electronic documents | Connecting data and technology |

| Cost | Higher setup and maintenance costs | Flexible setup and maintenance costs depending on scale |

| Security | Secure connection options available | Level of security depends on API security |

| Flexibility | Limited to sending documents | Nearly unlimited API options |

| Scalability | Handles large volumes of transactions | Unlimited scalability, but becomes more complicated to manage as you scale |

| Best Used For | Simplifying transaction updates reliably and securely | Automating workflows across your supply chain operations |

All About EDI

EDI enables two systems to send documents to each other in an electronic format. This data transmission happens automatically and replaces paper-based communication.

Here’s how sending an EDI file works:

- Document export: You order your system to send an EDI document such as an invoice or purchase order.

- Data formatting: A mapping software or translator turns the information in your document into a format your EDI system can read.

- EDI standard enforcement: Your EDI system converts the translated data into a structure that meets current EDI standards.

- File transmission: With your document ready to transmit, your EDI system sends it to middleware software or directly to your trading partner.

- Document receipt: Your partner receives your document through their EDI system. Depending on your transmission method, the systems involved might create a secure connection to ensure data privacy.

While EDI transmission has multiple layers, your software takes care of most of the process. So, on your end, you’ll send and receive documents without having to handle the smaller details.

The EDI Integration Process

Since EDI-based solutions have a long track record, modern technology doesn’t always have built-in integration options. Applications like Shopify often require you to create custom solutions to connect data through EDI. Fortunately, there are software developers and full-service solutions that can help you integrate EDI data with:

- Business-to-business (B2B) software like Microsoft Dynamics 365

- Enterprise resource planning (ERP) software like Sage 100

- Customer relationship management (CRM) software like Salesforce

- eCommerce software like Magento

EDI Advantages in the Supply Chain

The advantages EDI solutions offer to businesses in the supply chain include:

Less Manual Data Entry

By replacing document transfer with automatic transactions, EDI reduces the human error and costs associated with manual processes.

Stallion Express, a shipper for eCommerce companies, uses EDI for its transactional data. CEO Pramod Bhat says, “By adopting defined formats for communication with suppliers and partners, EDI lowers the inaccuracies that come with human data entry.” EDI also lowers the costs that come with paperwork and human labor by enabling real-time data exchange for Stallion Express.

Standard Format and Security for Data Transfer

Because EDI uses standardized formats and offers secure connections, many different industries count on its technology. These security, and industry standards allow industries with sensitive data, such as healthcare, to stay compliant. Some standards also apply in different countries than others, creating a common ground for international transactions.

EDI uses standards such as:

- ANSI ASC X12: Two of the biggest standards organizations in North America, the American National Standards Institute (ANSI) and the Accredited Standards Committee (ASC), created this standard. It started in North America and now finds use worldwide.

- UN/EDIFACT: This EDI language works across multiple industries and countries. It’s mostly popular in Europe, especially in the retail sector. But, other sectors like construction, logistics, and healthcare now count on it as well.

- ODETTE: Unlike the other, universal standards in this list, ODETTE specifically serves the European automotive industry. It provides tools for automating transactions in the automotive supply chain.

Also see: EDI Integrations Explained [Steps, Types and Benefits]

Popular With Established Businesses

While EDI is a much older technology than APIs, it’ll still be viable in the coming years because so many established businesses use it in their legacy systems. If you work with manufacturing or retail partners that have a lot of history, you have a good chance of coming across one that uses EDIs. Since EDI’s history goes back to the 1960s and these companies have already invested in the resources needed to use it, they keep it around.

Stallion Express works with a wide range of partners, some of which use EDI. While Stallion Express uses both EDI and APIs, its EDI transactions tend to happen with partners who need the standardized formats that EDI can offer. EDI keeps order processing, shipping notifications, and invoicing consistent for these partners.

Ideal for Large Volumes of Transactions

EDI can handle a large amount of data at once, making it ideal for businesses with a lot of transactions. This technology scales fairly easily as long as you have the infrastructure to receive all the data transmissions involved.

Metal Marker Manufacturing, a metal manufacturer, uses EDI to manage a high volume of information. President David Primrose says, “We started using EDI to improve how accurately we handle data and make our supply chain run more smoothly, especially when dealing with complex information exchange and high volumes of business transactions. [EDI’s] ability to process large amounts of information at once has been extremely valuable.”

Even though the company uses both supply chain APIs and EDI, Primrose says, “We prefer EDI for handling large numbers of standard transactions and complex supply chain information because it costs less in the long run and can process many transactions at once.”

Disadvantages of EDI for Merchants, Suppliers, and Manufacturers

Although EDI succeeds within its niche, it doesn’t perform as well outside that specialty. Keep these drawbacks in mind when considering EDIs:

Focused on Business Documents

If you need to transfer a business document, EDI can do the job – but it doesn’t suit most other uses. It often can’t handle communications with documents outside of compatible ones like:

- Invoices

- Payment orders

- Pricing catalogs

- Requests for quotations

- Advance shipment notices

EDI will be a great fit for your use case if you need to send a document on the above list or a similar one. But, outside of those types of transactions, another technology may be a better choice.

Fewer Customization Options Than APIs

Compared to APIs, EDI has fewer customization options, making it less flexible. You can choose your integration method, standards, and protocols, but not much else. Your options for connecting technologies can also be limited by EDI’s age and complexity.

Higher Barrier to Entry Than APIs

Getting started with EDI tends to require more money and technical knowledge than adopting APIs. EDI needs specific systems and technology to work that cost more to set up than API implementation. Plus, EDI setup needs specialized developers due to the technology’s uniqueness.

Recommended read: Decoding API Integration (Types, Use Cases & FAQs)

What Is EDI Best Suited for?

Bringing all the above points together, EDI works best for businesses that need to reliably perform transactions through digital documents. Since EDI focuses on document transfer alone, it provides a consistent way to transfer and update supply chain and financial data.

Thanks to this specialization, Kenko Tea, an eCommerce store, benefits from real-time business processes. Sam Speller, CEO and Founder, says, “We have real-time information about how much our suppliers have in stock, so we can ensure we have the right products and we don’t run out of products. For instance, our recent launch of a limited-run matcha mix hinged on accurate inventory levels. EDI meant we could forecast customer demand and order quantities in advance to avoid stockouts and maximize sales opportunities.”

APIs in Supply Chain Processes

Like EDI, APIs automate trading partner communications, but they work on a broader level. An API is a group of rules that determine how different systems interact. You can use API solutions to connect various software.

Let’s see how an API call works:

- Making an API call: You send a request to the server for the API you want to use. The API could represent whatever data or technology you want to connect.

- API processing: The API server processes the request and performs an action based on the input it receives.

- API response: The API server then responds to you with the requested data, a report of an action taken, a status code, or an error message.

While a business with an EDI system typically has just one EDI system, companies that use APIs often have multiple APIs from various sources.

How API Integration Works

Think of APIs as building blocks for integration. You can use them together to create a chain of actions among different software. In fact, APIs are one of the main technologies we use to integrate software in the DCKAP Integrator.

Generally, software companies provide the APIs themselves for developers to connect other applications with. You can find APIs for:

- eCommerce software like Magento

- ERP software like Epicor

- CRMs like HubSpot

- Just about any software you use for your business

The Strengths of APIs in the Supply Chain

APIs have many benefits for businesses involved in the supply chain, including:

Real-Time Interactions Between Any Software

With APIs existing for a wide range of technologies, it lets you exchange data from just about any source in real time. Even though EDI works just as quickly, it can only offer that speed for specific purposes.

The eCommerce business Groomsday uses APIs over EDI in part because of their speed. Owner Chris Bajda says:

“One of the biggest perks we’ve seen from using APIs is how much smoother our operations have become. Tasks like updating orders or managing inventory used to take time, and there was always a risk of errors when doing things manually. With APIs in place, those tasks happen automatically, and it’s been a huge time-saver.”

More Flexibility Than EDI

APIs offer much more flexibility than EDI due to their compatibility and customization options. This versatility allows for more business opportunities and better customer satisfaction.

At Groomsday, Badja chose APIs over EDI because of this flexibility. Badja explains, “I went with APIs for Groomsday because they give us more freedom to work with different systems. EDI might be great for older, more rigid setups, but we needed something that could easily connect with modern e-commerce platforms and third-party tools.”

Ability to Connect With Multiple Business Partners At Once

Thanks to APIs’ ability to link multiple systems and software, they also let you connect with more than one trading partner at once. B2B APIs’ flexibility and speed help you adapt to your partners’ technology to get real-time updates on your partners’ operations.

Let’s look at TechnoLynx, a software consulting agency that uses APIs to connect with partners in the supply chain. Founder and CEO Balázs Keszthelyi considers this use its biggest benefit. “For instance, when collaborating with manufacturing partners, we can access their inventory data instantly, allowing us to adjust our project timelines and resource allocations accordingly,” Keszthelyi says.

More Opportunities for Innovation

Newer technology and more options for connection lead to more opportunities for innovation. APIs have higher compatibility with new technology and ongoing updates to keep them current with the latest developments. Plus, with so many APIs out there, you can essentially create your own software to use them with.

Drawbacks of Supply Chain APIs

The flipside of APIs’ numerous options is its lack of a single source, creating issues such as:

More Factors to Manage Than EDIs

Your range of options for APIs can become a challenge if you decide to use multiple. Creating a full integration requires you to coordinate:

- The primary technologies you want to connect

- How you want to connect those technologies

- Whether you’ll need outsourced help to set up your integration

- Updates and maintenance for all of the APIs you use

And while APIs all operate on the same “language,” they still come from different providers, leading to variations. You’ll need to account for these differences as you build the best solution for your business.

Lack of Standardization

APIs do not have the standards for formatting and security that EDI does, creating a risk for sensitive data transfers. Not all APIs are necessarily data risks, but you will need to evaluate each API for its security as you add it. A lack of a standard format can also lead to more complicated data mapping.

Complexity of Scaling

You’ll have to consider every API you use as you scale, making scaling more complex as it happens. As you add more APIs to your integrations, you’ll have to consider the above factors for each API. After setup, you’ll also need to monitor the calls and errors for the entire mix of APIs you use.

What Are APIs Best Suited for?

APIs are best for connecting different software applications and data. Their high flexibility allows for automation in just about any app you or your trading partners use.

Pearl Lemon, a digital agency that works frequently with logistics and B2B clients, chooses APIs in situations that require fast action. CEO Deepak Shukla says, “We chose to implement APIs for real-time, flexible communication, particularly when we need quick access to live data, such as tracking shipments or updating inventory levels. APIs allow us to integrate with multiple platforms seamlessly, adapting to unique client needs without a heavy lift.”

Shukla adds, “For standard, frequent exchanges, EDI is rock solid. But when speed, flexibility, and customisation matter, APIs win the day.”

How to Work With Both EDI and APIs in Your Supply Chain Operations

Many of the businesses we consulted about their EDI and API use think both technologies play a crucial role. Don’t think of it as a battle of EDI vs. APIs. It’s just a matter of the right technology for your situation.

Metal Marker Manufacturing uses both technologies in its operations. Primrose says, “We use EDI for standardized, high-volume transactions and APIs for real-time, dynamic interactions. For example, EDI handles our bulk metal tag orders, while APIs manage our variable pricing updates and inventory checks.”

Primrose continues, “The benefits have been great. EDI reduced our order processing time by 60%, while APIs improved our supply chain visibility by providing instant access to crucial data. Because of this, choosing between EDI and APIs is like selecting the right metal for a specific tag application – it depends on your specific needs and circumstances.”

These three approaches to easy integration can help you achieve the right balance between the drawbacks and benefits of APIs and EDI:

Supplier-based integration

Some of the businesses we talked to match the technology they use with what their partners use in transactions. You could try this strategy if you prefer one for your internal operations but want to stay flexible.

For example, while APIs might be the answer for most of your integrations, older companies sometimes use EDIs in data transfer. In this situation, you could use EDI just with these partners and anyone else with high standards for formatting and security.

Purpose-based integration

Another way to organize your use of APIs vs. EDI is to choose based on purpose. Although both technologies transfer data, API leans more towards general use, while EDI specializes in documents. Some of the companies we talked to take this approach because of each technology’s different purposes.

Outsourced integration

It takes deep technical expertise to integrate EDI or APIs on their own, let alone when you want to use them together. A complete integration solution with knowledge of APIs and EDI can help you set up both technologies to fit your operations. Consider hiring one of these services to configure APIs and EDI for you to save the time and effort it takes to do it on your own.

Some of these solutions, such as DCKAP, provide software for you to manage your integrations after handoff. You’ll get to enjoy the ease of professional installation and the independence that comes with self-serve apps.

DCKAP Integrator: EDI and API Integration for Manufacturers and Distributors

Companies involved in supply chain management have an especially high number of apps and partners to manage, making integration more complicated than for other businesses. DCKAP Integrator helps B2B manufacturers and distributors connect different systems for better operational efficiency. These businesses choose DCKAP Integrator for:

- Fully custom solutions: Our team combines our knowledge of technology like logistics APIs and EDI to automate operations between applications. We configure solutions based on each client’s needs. For example, we helped Aliquantum handle its more than ten thousand SKUs by connecting BigCommerce and Distribution One.

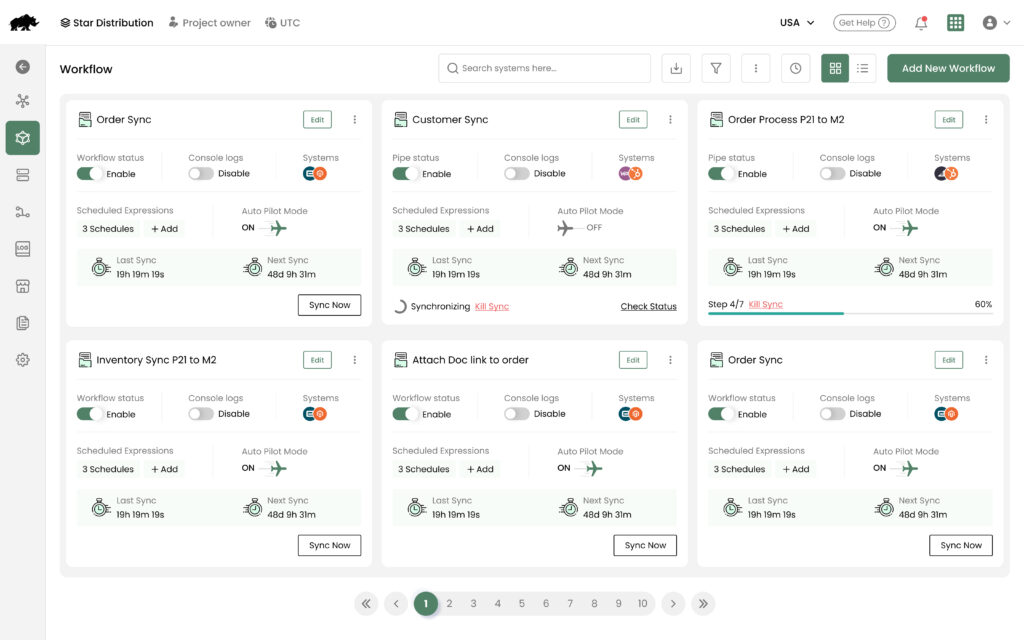

- Dedicated team and powerful software: DCKAP Integrator offers the benefits of a bespoke team and self-serve software. During the first few weeks, our team will discuss your goals with you and build DCKAP Integrator workflows based on those goals. Once we establish those workflows, we’ll hand your custom solution over to you.

- Ease of use: Once you have your custom-configured DCKAP Integrator app, it’ll be easy to monitor your integrations. It presents all of your workflows and integrations in a modern interface for simple access.

See DCKAP Integrator in Action

While there’s even more we could say about DCKAP Integrator’s benefits, why don’t you see them for yourself? Sign up for a live, 1:1 demo to see how the software works in real time. Give us some information about yourself, and we’ll schedule the demo at a time that works for you.

Contents